Case Study – Former Dry Cleaner San Rafael, California

Provect-IR® – In Situ Chemical Reduction Reagent for Source Area and Plume Remediation

Former Dry Cleaner: San Rafael, California

Contaminants of Interest: Chlorinated Volatile Organic Compounds (CVOCs)

Project Summary

At a former dry cleaner site in San Rafael, California, an in situ chemical reduction (ISCR) remedy was implemented to address chlorinated volatile organic compound (CVOC) contamination associated with a source release area and the resulting large dilute 3,000 ft long plume. The site was identified as a California Regional Water Board site under the Spills, Leaks, Investigation & Clean-Up (SLIC) Program in 2007. Off-site impact characterization was performed in 2013 under the direction of San Francisco Bay Regional Water Quality Control Board (SFBRWQCB). The investigation identified an area impacted by constituents of concern (COC) that were detected in groundwater up to a half mile east of the source area. The saturated sand zone encountered between approximately 15 and 25 feet below ground surface (ft bgs) appears to be the principal groundwater bearing unit with COC impacts. A Provect-IR® pilot injection program was proposed and implemented in a portion of the downgradient plume area during 2017. Following the successful pilot test implementation and additional site characterization activities, full-scale Provect-IR® injections were performed both on-site and off-site during 2021 and 2023.

Provect-IR® is a site-specific blend of unique reagents combined into a single product that optimizes the in situ reductive dechlorination of chlorinated VOC contamination in both soil and groundwater. This technology works by promoting synergistic interactions between zero valent iron (ZVI), hydrophilic, nutrient rich organic carbon sources, chemical oxygen scavengers, vitamins, and mineral sources. This patented combination of natural and food grade amendments promotes ISCR conditions for rapid and effective destruction of the targeted contaminants. Additionally, Provect-IR® is the only ISCR reagent to inhibit the production of methane during the requisite carbon fermentation process, which promotes more efficient use of the hydrogen donor while avoiding negative drawbacks associated with elevated methane.

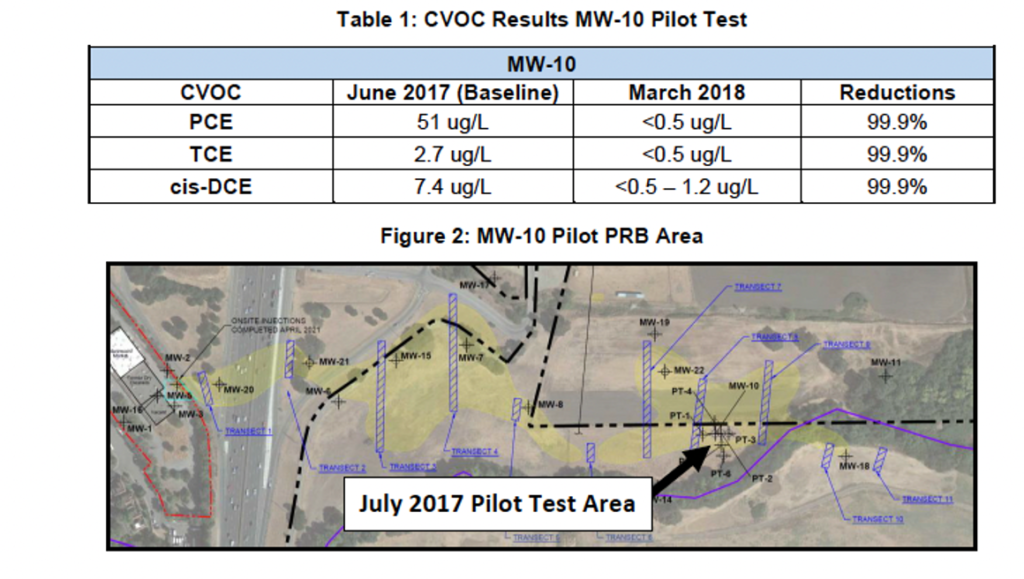

Pilot Permeable Reactive Barrier Program

In July 2017, a permeable reactive barrier (PRB) pilot test was conducted in the downgradient portion of the plume (Figure 2) that included 6,800 lbs of Provect-IR® and 8 liters of Dehalococcoides (DHC) inoculum, specifically KB-1 provided by SiREM. The Provect-IR® and DHC were applied via six temporary direct push injection locations. The pilot test PRB was 84 feet (ft) in length with an approximate 15 ft vertical target interval from 15 to 30 ft bgs. Monitoring well MW-10 located within the PRB injection radius of influence (ROI) was the primary performance monitoring location. Additional temporary monitoring wells and groundwater grab samples were utilized to further confirm effectiveness and reagent distribution. Within 8 months following pilot implementation, the PCE and TCE groundwater concentrations at MW-10 were reduced to <0.5 ug/L (Table 1) with negative shifts in oxidation reduction potential (ORP) observed.

Full-Scale Remediation Plan

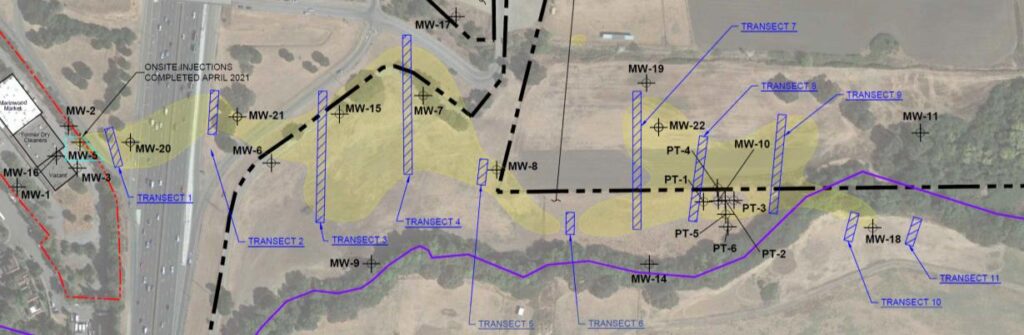

Based on the success of the pilot test, 11 offsite Provect-IR® PRBs and one onsite injection were designed to address the entire plume and target areas with PCE concentrations in excess of 30 ug/L. The PRBs were designed to intersect the large dilute plume and reduce PCE concentrations to below the SFBRWQCB Cleanup Level of 5 ug/L. The target monitoring wells were located 30 to 100 ft downgradient from the Provect-IR® PRBs. Concurrent with that portion of the project, the source zone (i.e., the Eastern Hot Zone) was also treated with Provect-IR® injections. Figure 3 below shows the barrier locations across the site within the >30 ug/L PCE plume that is approximately 3,000 linear ft. The remedial program was developed by RMD Environmental Solutions Inc. (a subsidiary of Citadel EHS) and Provectus Environmental Products, Inc.

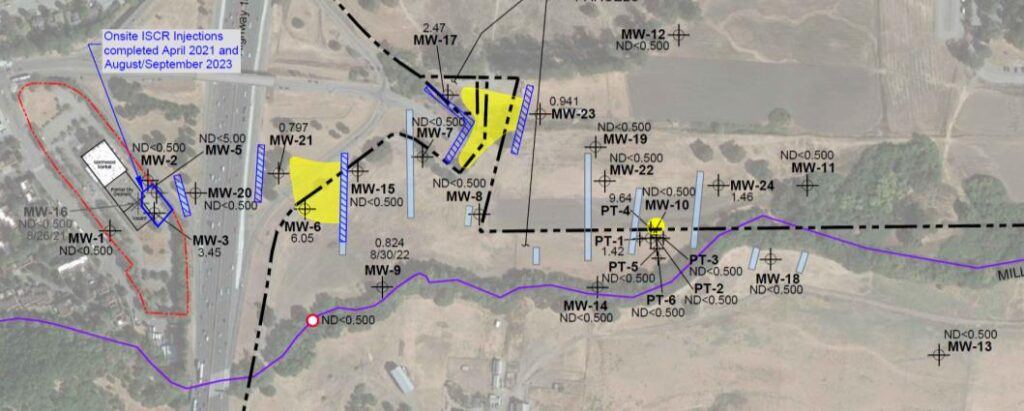

(Provectus) with in situ implementation provided by Gregg Drilling. During the timeframe of June through August 2021, a total of approximately 67,900 pounds of Provect-IR® and 77 liters of DHC were injected within 12 strategic areas. The lengths of the PRBs varied from 75 to 400 linear ft with vertical injection intervals based on the localized subsurface conditions (ranging from 14 to 42 ft bgs). Due to the success of the 2021 full-scale injection program, an additional Provect-IR® injection event occurred between July and September 2023 to target impacted areas outside of the original scope of work. The second full-scale phase included a total of approximately 64,750 pounds of Provect-IR® and 66 liters of DHC injected within additional treatment areas.

Figure 3: 2021 Full-Scale PRB Locations and PCE >30 ug/L

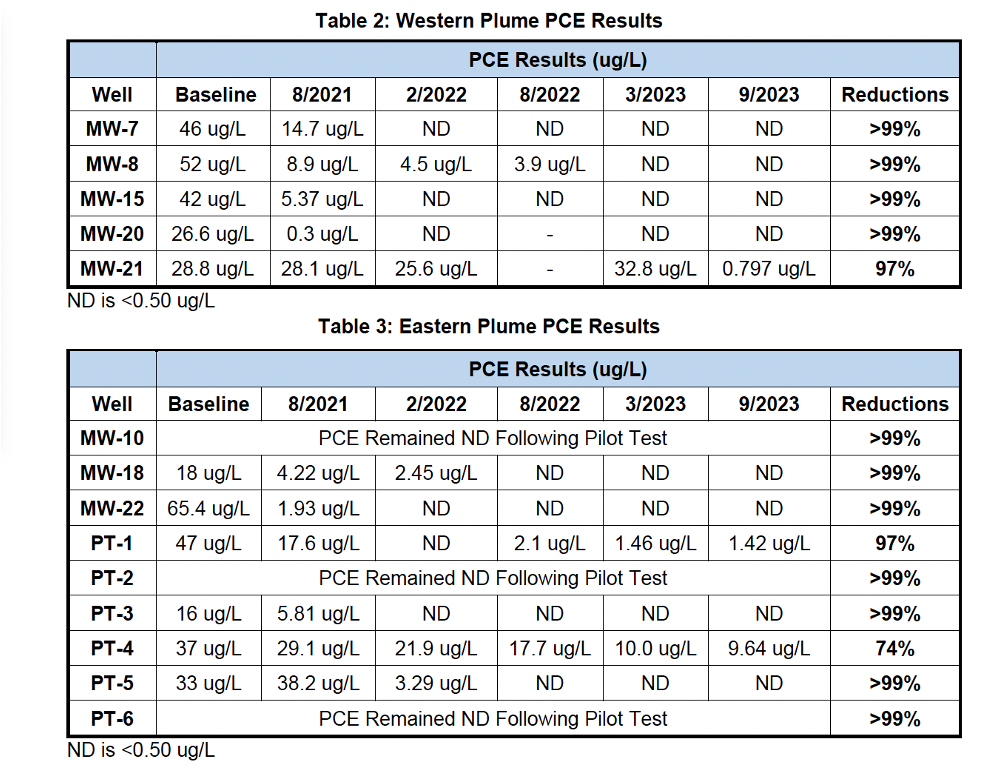

Treatment Program Results

Analytical results for groundwater samples collected after Provect-IR® injections indicate substantial PCE reductions across the 3,000 ft plume. Figure 4 displays the distribution of the >5 ug/L PCE plume that is currently limited to only three areas including one area that was not directly targeted by the ISCR remedy. Specifically, within 20 months following Provect-IR® implementation, PCE concentration reductions of >99% were observed in 11 of the 14 target monitoring wells with only one monitoring well within the PRB target area above PCE standards of 5 ug/L. Table 2 and Table 3 demonstrate the baseline PCE groundwater concentrations from samples collected between May 2020 and May 2021 and outline post-treatment PCE groundwater concentrations for the sample location over a 26 month period.

Figure 4: 2023 PCE Plume Results and PCE >5 ug/L

Project Conclusions

Following the full-scale Provect-IR® injection events, significant PCE reductions were observed at all target monitoring wells. The 3,000 linear ft PCE plume no longer exists with only one monitoring well within the PRB target area above PCE standards of 5 ug/L. Provect-IR® is an aggressive ISCR remedial technology that provides long-term CVOC destruction. The Provect-IR® PRBs were designed to have a lifespan >7 years and therefore, additional CVOC reductions are anticipated as the biotic and abiotic reactions continue.

Please contact our office at (815) 650-2230 or via email at info@provectusenv.com for additional information regarding this project or our technologies.